In the 1950’s, Eldo J. (Bud) Coons and his brother had a business building campers in Pomona, CA. When they decided to expand “Coons Custom Coach” in 1957, Bud relocated to Oswego, KS, and opened a new branch office. Two years later, the very first camper, the “Dreamer Coach,” rolled off the production line.

By 1962, the Coons had purchased the Scotsman Trailer Company in Coffeyville, KS, and were making plans to manufacture fiberglass motorhomes. Just 3 years later, the company introduced their first motorhome to the public.

The 1970’s oil and gas crisis impacted the company’s business, and they faced a decision: weather the reduced demand for motorhomes, or diversify. The company diversified, adding people-moving vehicles (buses) to their line of products.

The company was purchased by the Borg-Warner Corporation in 1968, and as a condition of the acquisition, remained in Oswego under the leadership of Coons. It changed hands twice before Coons bought it back in 1973.

In 1988, the company was purchased by Dick Seyboldt and Wayne Lowe. The next year, management exited the motorhome product to focus exclusively on composite buses. Under Dick’s 28-year leadership, the company grew a loyal customer following by consistently delivering on customer expectations.

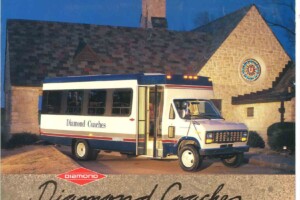

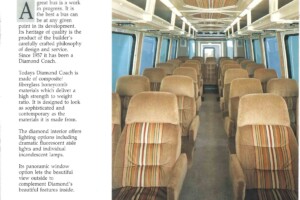

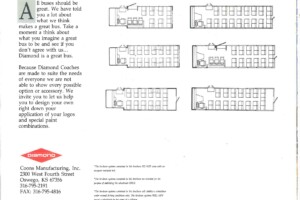

Since 1989, Diamond Coach has manufactured rust-free, impact-resistant buses that provide superior resale value. Diamond buses come in several models, accommodating 16-28 people, and are noted for providing a smooth, quiet ride. These buses are used for a variety of applications, including hotels, transit and parking authorities, healthcare, tour operators, sports clubs, and churches.

Diamond markets its products through a nation-wide team of independent dealers. Diamond Coach is headquartered in Oswego, KS, and is part of the B12 Transportation Group of Kansas City, MO.

Click here to learn more about what makes Diamond different.